High Quality Rugs and Carpets

At Rugs Land, we take pride in offering a stunning collection of high-quality rugs and carpets that cater to all tastes and preferences. Our curated selection spans across various styles, including Oriental, Persian, Afghan, Indian, and many more. Each piece in our collection is a testament to craftsmanship, bringing the timeless beauty of traditional weaving techniques to your home.

Explore Our Diverse Range

Our extensive range includes:

- Oriental Rugs: Authentic pieces that add a touch of elegance to any room.

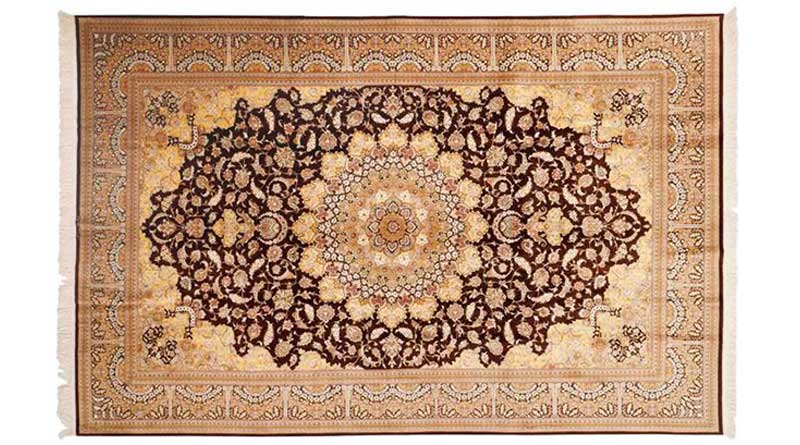

- Persian Carpets: Known for their intricate designs and rich history.

- Afghan and Indian Rugs: Unique patterns and vibrant colours that stand out.

- Antique and Vintage Rugs: Classic pieces that bring historical charm.

- Modern and Contemporary Designs: For those who prefer a more current aesthetic.

Quality and Expertise

We are committed to offering only the finest rugs, ensuring each piece is crafted with the highest standards. Whether you are looking for a luxurious silk carpet or a durable wool rug, our collection promises exceptional quality and longevity. Step into the world of Rugs Land and discover the perfect rug that tells your story. Visit our website, explore our collections, and experience the elegance and comfort of our exquisite rugs.

- What is the Difference Between a Persian Rug and a Persian Carpet?What is the Difference Between a Persian Rug and a Persian Carpet? Persian rugs and Persian carpets are renowned for their exquisite beauty, intricate designs, and exceptional craftsmanship. While these terms are often used interchangeably, there are subtle differences that set them apart. Understanding these differences between Persian rug and Persian carpet distinctions can help you appreciate the unique qualities of each. Handwoven Artistry Both Persian rugs and Persian carpets are handwoven or hand-knotted, showcasing the meticulous skill of Iranian weavers. This artisanal process involves tying individual strands of wool or silk onto the rug’s foundation by hand, creating intricate patterns and designs. This painstaking technique ensures that each piece is unique and of the highest quality. The craftsmanship involved in making these rugs and carpets is a significant factor contributing to their value and desirability. Differences in Size One of the primary differences between a Persian rug and a Persian carpet is their size. Traditionally, the term “rug” is used to describe smaller pieces, while “carpet” refers to larger ones. Rugs are typically used as decorative pieces, often placed in smaller spaces like entryways, kitchens, or bathrooms. In contrast, carpets cover larger areas and are commonly found in living […]

- Why Are Persian Rugs So Expensive?Why Are Persian Rugs So Expensive? High-Quality Persian rugs are renowned for their exquisite beauty, intricate designs, and unparalleled craftsmanship. However, these attributes also contribute to their high cost. Understanding why Persian rugs are so expensive requires a closer look at their creation process, materials, and cultural significance. Hand-Knotted Expertise The primary reason for the high price of Persian rugs is the meticulous hand-knotting process. Each individual strand of wool or silk is meticulously tied onto the rug’s foundation by hand. This painstaking process is incredibly time-consuming, often taking months or even years to complete a single rug. The level of detail and precision required in hand-knotting ensures that each Persian rug is a unique piece of art, reflecting the skill and dedication of the weaver. Quality of Materials The materials used in Persian rugs are another significant factor contributing to their cost. Persian rugs are typically made from high-quality, all-natural materials such as wool and silk. Wool provides durability and resilience, making the rugs long-lasting and robust. Silk, on the other hand, adds a luxurious sheen and softness, enhancing the rug’s aesthetic appeal. Additionally, the dyes used in Persian rugs are derived from natural sources, such as plants and […]

- What is Special About Persian Rugs?What is Special About Persian Rugs? The Rich Heritage of Persian Rugs Persian rugs are renowned worldwide not just as floor coverings but as exquisite works of art. These rugs, originating from Iran, have a history that dates back over 2,500 years, making them a significant part of human cultural heritage. The meticulous craftsmanship, vibrant colours, and intricate patterns make Persian rugs highly desirable and valuable. High-Quality Natural Materials One of the standout features of Persian rugs is their use of high-quality, all-natural materials. These rugs are traditionally made from wool, silk, or a blend of both. Wool provides durability and resilience, while silk offers a luxurious sheen and a softer texture. Unlike many modern rugs that use synthetic fibres, Persian rugs rely on these natural materials, which contribute to their longevity and eco-friendliness. Furthermore, the dyes used in Persian rugs are derived from natural sources, such as plants and insects, ensuring rich, lasting colours that do not fade easily. Intricate and Meaningful Designs The designs of Persian rugs are another aspect that sets them apart. Each rug tells a story, with patterns and motifs that often have deep symbolic meanings. Common themes include floral patterns, geometric shapes, and intricate […]

-

Turkmenistan Carpets

Exploring the Rich Heritage of Turkmenistan Carpets Turkmenistan carpets, renowned for their intricate designs and cultural significance, embody the rich tapestry of Central Asian craftsmanship. These exquisite rugs originate from various regions, including Uzbekistan, Turkmenistan, East Turkistan, Afghanistan, and Baluchistan. The artistry of Turkmenistan carpets encompasses several distinctive styles and weaving techniques, each contributing to…

-

Caucasian Carpets

The Allure of Caucasian Carpets: A Brief Exploration Caucasian carpets, renowned for their intricate designs and rich history, originate from regions south, east, and north of the Caucasus mountain range. These carpets, particularly those crafted before 1925, are highly prized for their unique aesthetic and cultural significance. They can be broadly categorised into five distinct…

-

Tibetan carpets

Tibetan carpets, renowned for their intricate craftsmanship and cultural significance, originate from the high-altitude region of Tibet, where nomadic traditions and a deep reverence for artistry converge. Historically, these carpets were crafted by Tibetan artisans, utilizing wool sourced from local sheep and goats—a vital economic resource in the region. Over time, the term “Tibetan carpets”…

-

Turkish carpets

The Rich Legacy of Turkish Carpets Turkish carpets, also known as Anatolian carpets, boast a rich history and a reputation for exquisite craftsmanship. The oldest known Turkish carpets date back to the 13th century and originate from Konya, a historic centre of Turkish carpet manufacturing. These carpets are known for their durability, intricate designs, and…

-

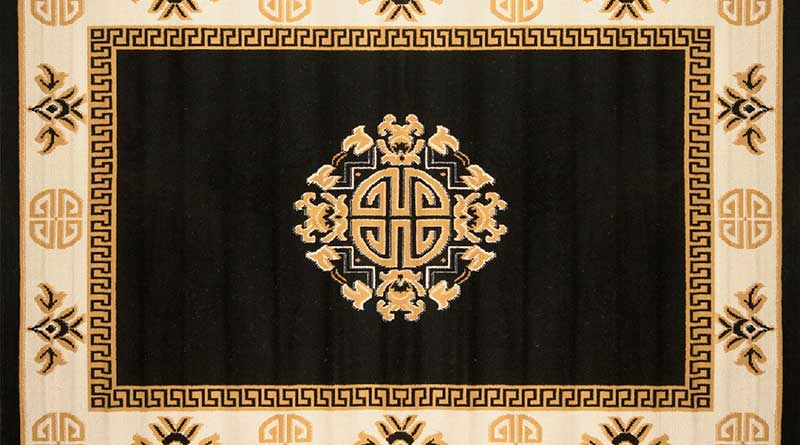

Chinese Carpets

The Rich Tradition of Chinese Carpets China boasts a long and esteemed history of carpet weaving, with the earliest examples dating back over 2,000 years. Initially, these carpets were primarily used in imperial courts, reflecting the grandeur and sophistication of Chinese craftsmanship. The art of knotting carpets in China, however, became prominent between the 15th…

-

East Turkestan Carpets

The Unique Beauty of East Turkestan Carpets East Turkestan carpets, also known as Xinjiang carpets, are distinguished by their intricate designs and rich cultural heritage. Originating from the northwest region of China, particularly in Xinjiang, these carpets are a testament to the region’s diverse influences, including Chinese and Turkmenistan patterns. Historical Significance and Production Centres…

-

European carpets

The Rich Legacy of European Carpets: A Journey Through Time European carpets have a storied history, marked by exquisite craftsmanship and diverse influences. From the intricate designs of French Savonnerie carpets to the bold patterns of Spanish rugs, each region has contributed uniquely to the evolution of carpet weaving in Europe. The Arrival of Oriental…

-

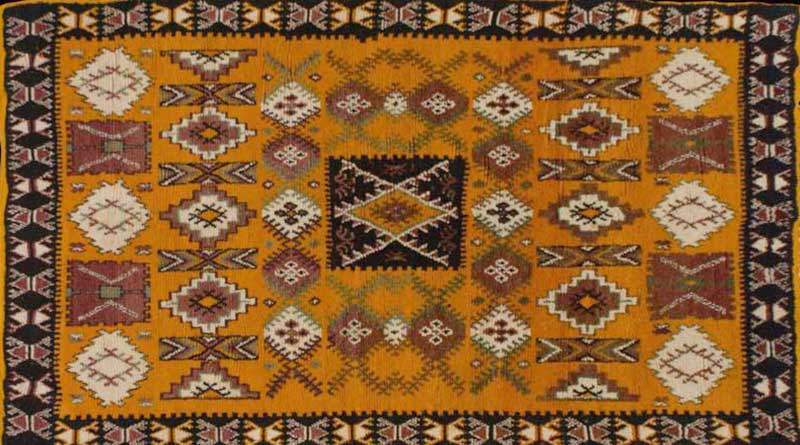

North African carpets

Exploring the Rich Heritage of North African Carpets North African carpets, celebrated for their intricate designs and vibrant history, originate from Morocco, Tunisia, and Egypt. These rugs reflect the rich cultural heritage and weaving traditions of their respective regions, each contributing unique styles and patterns. The Carpets of Tunisia The art of handmade carpet weaving…

-

Persian Kelim Rugs

Unveiling the Beauty of Persian Kelim Rugs Persian Kelim rugs, renowned for their intricate designs and vibrant colours, are masterpieces of weaving artistry. Unlike traditional hand-knotted rugs, Kelims are flat-woven, resulting in a fabric-like texture with no pile. This unique characteristic makes them both lightweight and versatile, suitable for various uses beyond just floor coverings.…